Unitma Digital Histology

Product Catalogue

* Premade Recipient Block

* Manual Tissue Microarrayer

* Automated Tissue Microarrayers

* Recipient Block Mold Kit

* Paraffin Block Trimmer

Tissue Microarray (TMA)

Tissue Microarrays are a collection of multiple tissue cores that are arranged in columns and rows inside a paraffin

block allowing for histological analysis. They are a crucial tool in the analysis of gene and protein expression levels in

samples from normal and diseased specimens. Further, they are useful in the early-stage discovery of gene targets

in genomic research, validating targets, testing, and optimization of diagnostic tests, and in the quality control of

molecular detection schemes.

And the TMA technology not only makes decrease the reagent, time, and human resource below one sixtieth but

also can be applied to most of the know-how about tissues for immunohistochemistry, in situ hybridization, FISH

and in situ PCR.

TMA advantages

• The use of relatively small tissue cores to be positioned onto a unique slide allows simultaneous histological analysis

of hundreds of samples.

• High throughput screening of expression

• Reduction of the number of slides to be mounted and analyzed → Time saving

• Reduction of the amount of reagents and antibodies used → Money saving

• Analysis of various biological specimens under uniform reaction conditions → Increasing the consistency of the

results

• Saving of precious biological samples and possibility to re-use donor blocks

UNITMA TMA technique

In conventional Tissue Microarray techniques, all the users have to prepare for their recipient blocks by drilling the

dummy paraffin blocks manually prior to starting TMA work.

But Unitma developed the premade paraffin recipient blocks for the first time in the world. The premade recipient

blocks have the well rounded hole matrix suitable for the digital histologic analysis.

Furthermore, Unitma’s premade recipient block brings to save the time and cost in preparation of the desired

recipient blocks manually and high throughput with a higher TMA success rate up to 99%.

Based on the core technology, Unitma developed the manual and automated tissue microarrayers and has been

supplying the most innovative instruments with the premade recipient blocks to worldwide customers as the best

solution for the digital histology.Recently Unitma also launched the automated paraffin block trimmer which can

trim the paraffin residues around the paraffin embedded tissue blocks without any damages to the sample tissues

and any injuries during the trimming work by the conventional trimming way. This instrument is only a paraffin block

trimmer without any competitive instruments in the current world market.Today, Unitma is continuously developing

new technologies to change the existing histologic techniques.

Premade Recipient Blocks

Automated Tissue Microarrayer UATM-272B

Manual Tissue Microarrayer

Recipient Block Mold Kit

Automated Tissue Microarrayer UATM-272A

Paraffin Block Trimmer

02 03

Certification Premade Recipient Block &

Recipient Block Builder

Manual Tissue Microarrayer

Automated Tissue Microarrayer

Paraffin Block Trimmer

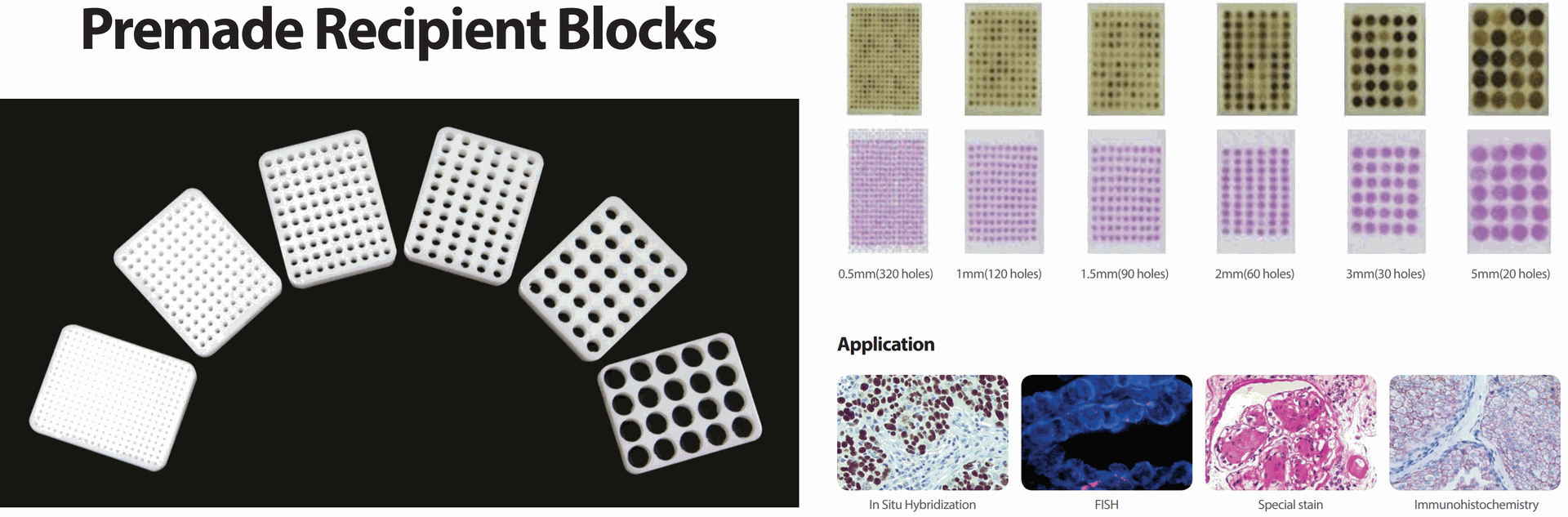

Premade Recipient Blocks

Unitma provides the premade recipient blocks

patented in global to save the valuable time and cost

in creating the recipient blocks additionally before

starting TMA work.

The premade recipient block is made of special

material which melts when heated at about 70 °C for

30~60minutes.

The blocks have evenly spaced round wells arranged

in a square matrix which conforms to digital

pathology trend.

Currently, six different sized blocks are available

0.5mm (320 holes), 1mm (120 holes), 1.5mm (90

holes), 2mm (60 holes), 3mm (30 holes), 5mm (20

holes)

The blocks of 1, 1.5, 2, 3, 5mm applicable to manual

Tissue Microarrayer while the blocks of 0.5, 1, 1.5,

2mm applicable to Automated Tissue Microarrayer

(UATM-272B)

Features

• TMA success rate up to 99%

• Maintains tissue integrity during embedding

• Up to 300 tissue slices per a block

• High durability during microarraying

• Standardized block configuration for the simple

image analysis

• Saving the additional time and cost in preparation of

recipient blocks

• Well rounded hole matrix suitable for digital

pathology

• Ready-to-use paraffin recipient block

• Compact design and versatility

• No dedicated space required for TMA block

formation

In Situ Hybridization

0.5mm(320 holes) 1mm(120 holes) 1.5mm(90 holes) 2mm(60 holes) 3mm(30 holes) 5mm(20 holes)

FISH Special stain Immunohistochemistry

Product name Premade Recipient Block

Model Number Core size Weight Number of cores

UB06-0.5 0.5 mm 3.4g 320 (16 x 20) holes

UB06-1 1 mm 3.2g 120 (10 x 12) holes

UB06-1.5 1.5 mm 2.8g 90 (9 x 10) holes

UB06-2 2 mm 2.5g 60 (6 x 10) holes

UB06-3 3 mm 2.5g 30 (5 x 6) holes

UB06-5 5 mm 1.8g 20 (4 x 5) holes

Dimension 24 x 30 x 5.5 mm

Color and odor White, odorless

Physical state and appearance Solid

Storage temperature Room temperature

Operating temparature 5°C ~35°C

Composition Paraffin plus special materials

Purpose of use Research purpose only

Certification ISO, CE

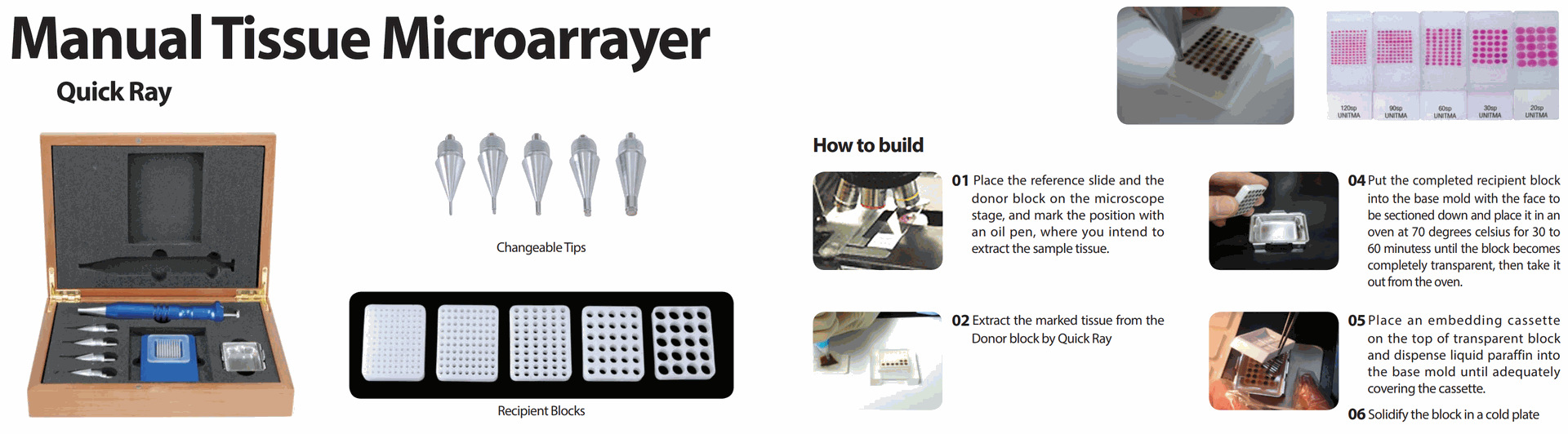

Manual Tissue Microarrayer

The newest technique for superior

quality tissue microarrays (TMAs)

The Quick Ray system represents the newest technique

available for producing superior quality Tissue Microarrays

(TMAs) in less time than with traditional methods at a

fraction of the cost.

The Quick Ray technique produces superior quality

TMAs in less time than with traditional methods, and

accomplishes finished products at a fraction of the cost.

The Quick Ray uses a hollowed tip to remove tissue

cores as small as 1mm from paraffin-embedded tissue

(donor block). The extracted tissue is then inserted into

a preformed recipient block-the Quick Ray System is

the only system available that uses a preformed paraffin

recipient block.

The finished block is sectioned using a microtome; the

sections are mounted on glass slides and then stained.

Each TMA block can be cut into 300~400 sections at

4~5μ, which can then be subjected to independent

tests. Common tests include immunohistochemistry and

fluorescent in situ hybridization. Compact design and

versatility make building a Quick Ray TMA astoundingly

simple. The construction of a TMA block can be done on

any clean counter, and does not require a dedicated space.

Features

• Portable and easy to handle

• Shortening the TMA work

• Smarter arrayer compared to conventional products

• Easy to carry and to make the array block anytime &

anywhere

• Inexperienced pathologist can be easily familiar with

the kit

• Simple procedure for creating the blocks

• Easy to create the various sized blocks by using the

premade recipient blocks

• Save the time in preparation of the recipient blocks

Recipient Blocks

Changeable Tips

01 Place the reference slide and the

donor block on the microscope

stage, and mark the position with

an oil pen, where you intend to

extract the sample tissue.

04Put the completed recipient block

into the base mold with the face to

be sectioned down and place it in an

oven at 70 degrees celsius for 30 to

60 minutess until the block becomes

completely transparent, then take it

out from the oven.

02 Extract the marked tissue from the

Donor block by Quick Ray

05Place an embedding cassette

on the top of transparent block

and dispense liquid paraffin into

the base mold until adequately

covering the cassette.

06 Solidify the block in a cold plate

03Deliver the extracted tissue into

the corresponding holes of the

recipient block supplied by UNIMTA

07 Sectioning by a microtome

08 Follow the next steps

How to build

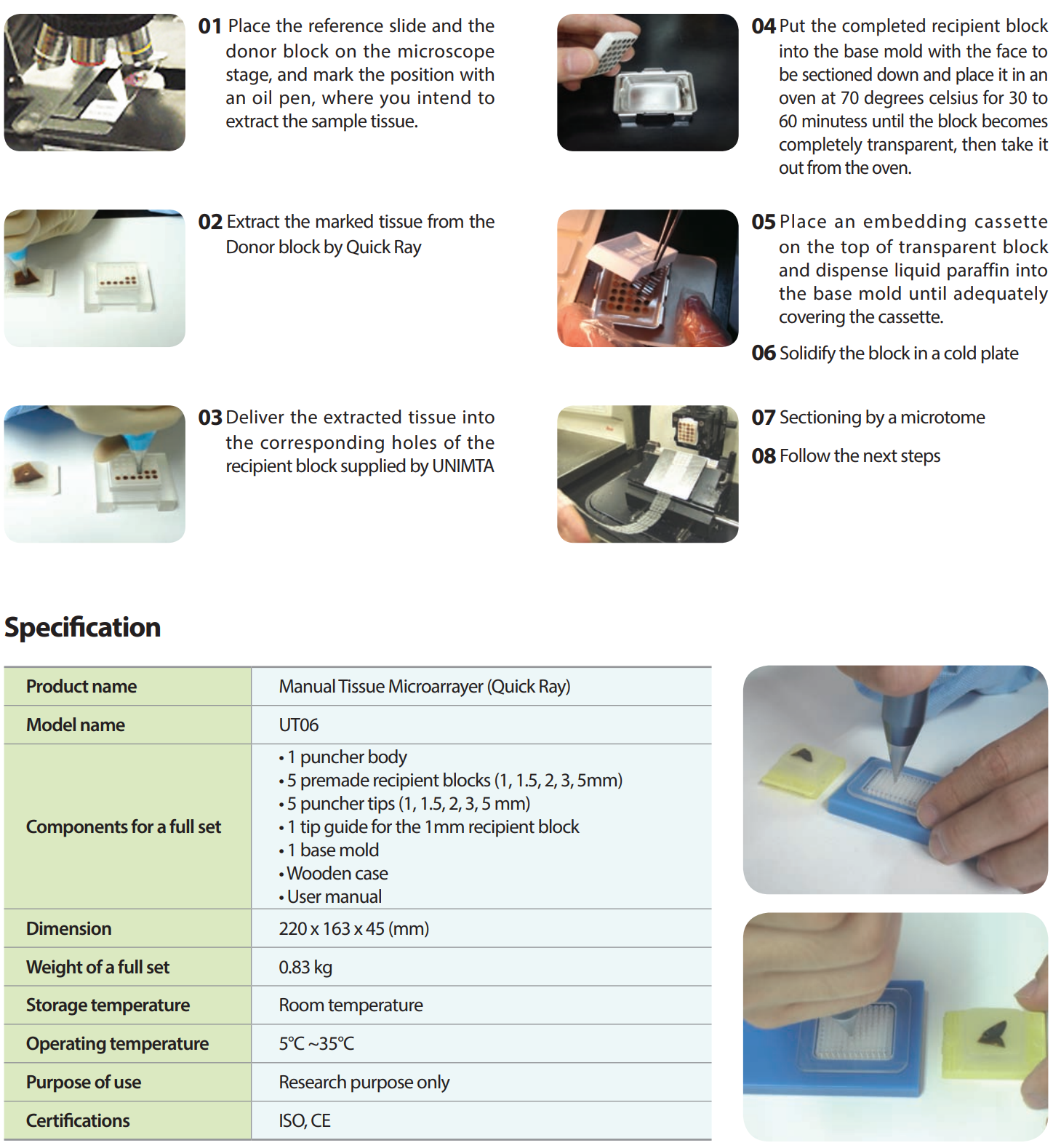

Specification

Product name Manual Tissue Microarrayer (Quick Ray)

Model name UT06

Components for a full set

• 1 puncher body

• 5 premade recipient blocks (1, 1.5, 2, 3, 5mm)

• 5 puncher tips (1, 1.5, 2, 3, 5 mm)

• 1 tip guide for the 1mm recipient block

• 1 base mold

• Wooden case

• User manual

Dimension 220 x 163 x 45 (mm)

Weight of a full set 0.83 kg

Storage temperature Room temperature

Operating temperature 5°C ~35°C

Purpose of use Research purpose only

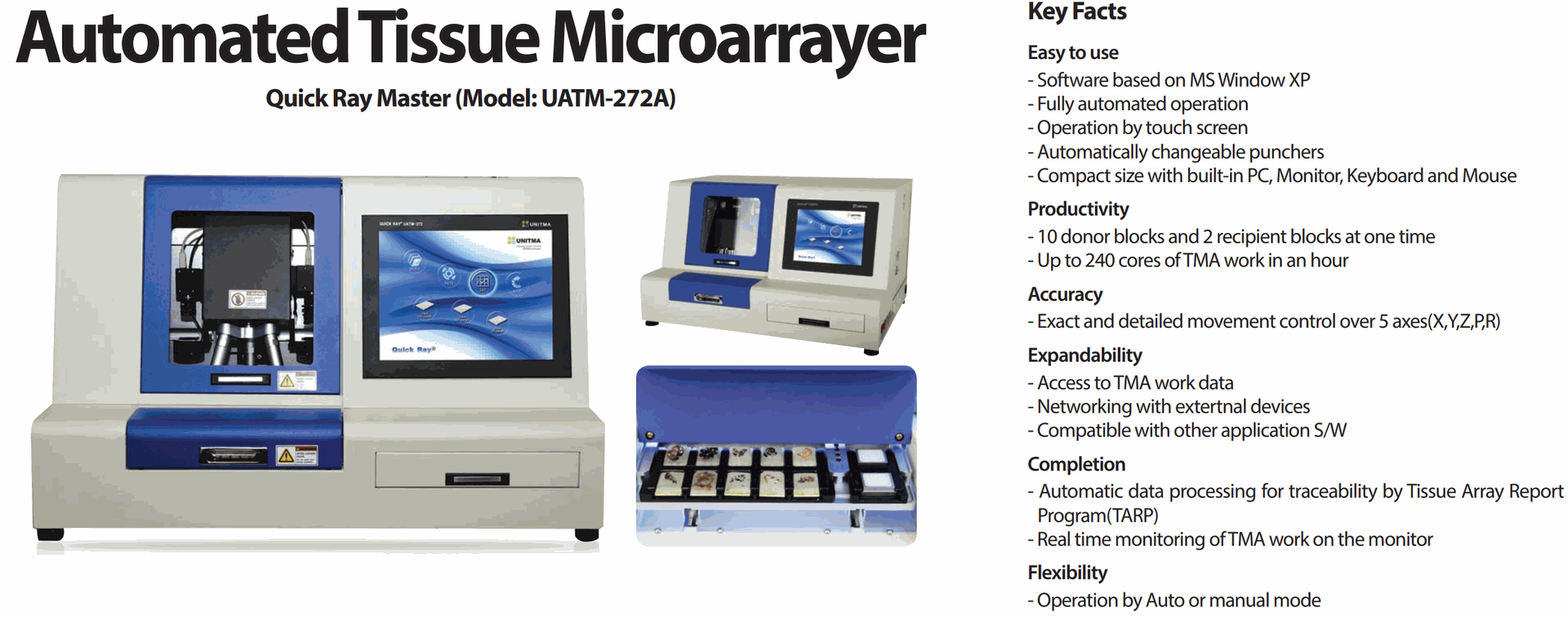

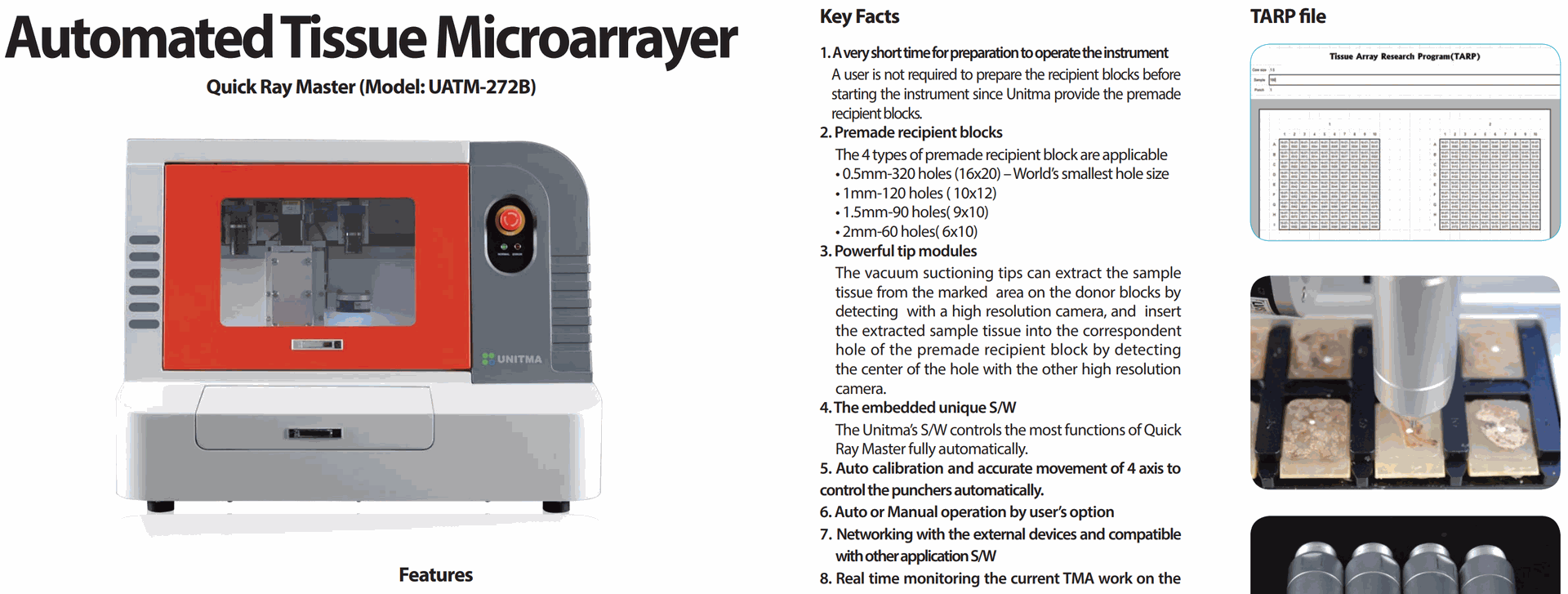

Automated Tissue Microarrayer

Quick Ray Master is an automated tissue microarrayer

running by the built-in PC.

The instrument extracts the sample tissues from the donor

blocks and delivers the extracted sample tissues into

the correspondent hole of the premade recipient block

automatically.

And the researcher can access to the data file for the

current TMA work by using the Tissue Array Report

Program (TARP) developed by UNITMA.

The researchers can choose one of the 3 rotary type tips

simply by using unique UNITMA software. The instrument

can be connected to the external devices such as USB,

monitors, printers and etc.

The instrument provides economical efficiency in time,

quality, and cost of tissue preparation by fully automating

tissue microarraying process.

Features

• Analysis of many patient tissue samples simultaneously

• Conserves tumors, biopses and other precious

biological samples

• Conserves antibodies and other expensive reagents

• Improves assay precision through sample and

patient multi-plexing

• Applicable to mRNA and protein expression analysis

• Miniaturize and automate immunohistochemistry, in

situ hybridization, FISH, and in situ PCR

• High-speed preparation of tissue microarray blocks

• Maintains tissue integrity during embedding

• Up to 300 tissues slices per recipient block

• Standardized block configuration simply image analysis

• Prepare up to 240 tissue cores per hour

• TMA success rate up to 99%

• Tissue array circle time 15secs

• Positional accuracy of 5μm at recipient blocks

Key Facts

Specification

List Description

Product name Quick Ray Master (Model : UATM-272A)

Instrument type Automated Tissue Microarrayer

Punch type Rotary puncher(1mm, 2mm, 3mm)

Power supply 100 to 120 VAC, 200 to 240 VAC / 50~60Hz

Space required 953 x 703 x 610mm (W x D x H)

Weight 148kg

Stage capacity 10 donor blocks and 2 recipient blocks

Speed 1 cycle time : 15 seconds (Pick & Place)

Monitor LCD monitor 15"(1024x768) with a touch screen

Camera resolution Camera 1 : 1280 x 1024, Camera 2 : 2,592 x 1,944 (pixels)

Operating system Unique UNITMA S/W by MS Window XP

Recipient block Premade recipient block to be supplied by UNITMA

Certifications ISO, CE, FCC, UL

Quick Ray Master (Model: UATM-272A)

Easy to use

- Software based on MS Window XP

- Fully automated operation

- Operation by touch screen

- Automatically changeable punchers

- Compact size with built-in PC, Monitor, Keyboard and Mouse

Productivity

- 10 donor blocks and 2 recipient blocks at one time

- Up to 240 cores of TMA work in an hour

Accuracy

- Exact and detailed movement control over 5 axes(X,Y,Z,P,R)

Expandability

- Access to TMA work data

- Networking with extertnal devices

- Compatible with other application S/W

Completion

- Automatic data processing for traceability by Tissue Array Report

Program(TARP)

- Real time monitoring of TMA work on the monitor

Flexibility

- Operation by Auto or manual mode

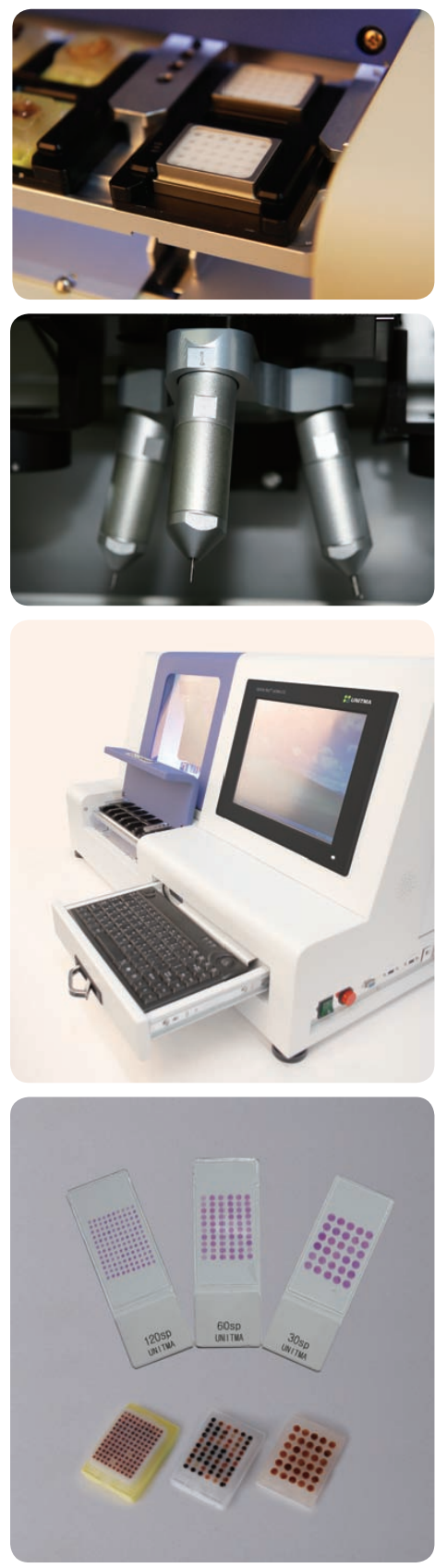

Automated Tissue Microarrayer Key Facts TARP file

Specification

Product name Quick Ray Master (Model : UATM-272B)

Instrument type Automated Tissue Microarrayer

Tip type Changeable Tips (0.5mm, 1mm, 1.5mm, 2mm)

Power supply 220 VAC, 50/60Hz

Dimension (W x D x H) 750 x 600 x 600 (mm)

Weight 80kg

Capacity 10 donor blocks and 2 recipient blocks

Speed 1 cycle time : 10 seconds

Camera resolution 2,592 x 1944 (pixels)

Operating system Unique UNITMA S/W by Window 7

Recipient block Unitma’s premade recipient blocks

Certifications ISO, CE, FCC, UL

Quick Ray Master (Model: UATM-272B)

1. A very short time for preparation to operate the instrument

A user is not required to prepare the recipient blocks before

starting the instrument since Unitma provide the premade

recipient blocks.

2. Premade recipient blocks

The 4 types of premade recipient block are applicable

• 0.5mm-320 holes (16x20) – World’s smallest hole size

• 1mm-120 holes ( 10x12)

• 1.5mm-90 holes( 9x10)

• 2mm-60 holes( 6x10)

3. Powerful tip modules

The vacuum suctioning tips can extract the sample

tissue from the marked area on the donor blocks by

detecting with a high resolution camera, and insert

the extracted sample tissue into the correspondent

hole of the premade recipient block by detecting

the center of the hole with the other high resolution

camera.

4. The embedded unique S/W

The Unitma’s S/W controls the most functions of Quick

Ray Master fully automatically.

5. Auto calibration and accurate movement of 4 axis to

control the punchers automatically.

6. Auto or Manual operation by user’s option

7. Networking with the external devices and compatible

with other application S/W

8. Real time monitoring the current TMA work on the

monitor

9. High productivity up to 240 holes per hour

10. Not needed the measurement of the donor block

height

11. Smarter and easier User Interface to run the instrument.

12. Easy TMA data management by Excel data sheet

Quick Ray Master is an automated tissue microarrayer

running by simply connecting to user’s computer

through USB port. The system extracts the sample

tissues from the donor blocks and delivers the

extracted sample tissues into the correspondent hole

of the premade recipient block automatically. And the

researcher can access the data file for the current TMA

work by using the Tissue Array Report Program (TARP)

developed by UNITMA.

The 4 different sized tips are manually changeable to

associate with the desired core size of the recipient

blocks: 0.5mm(320 holes), 1mm(120 holes), 1.5mm(90

holes), 2mm(60 holes). UATM-272B is smarter

instrument compared to UATM-272A, and is designed

for the users to be easily familiar with.

The instrument provides economical efficiency in

time, quality, and cost of tissue preparation by fully

automating tissue microarraying process.

Features

• Analysis of many patient tissue samples simultaneously

• Conserves tumors, biopses and other precious

biological samples

• Conserves antibodies and other expensive reagents

• Improves array precision through sample and patient

multi-plexing

• Applicable to mRNA and protein expression analysis

• Miniaturize and automate immunohistochemistry, in

situ hybridization, FISH, and in situ PCR

• High-speed preparation of tissue microarray blocks

• Maintains tissue integrity during embedding

• Up to 300 tissues slices per recipient block

• Standardized block configuration simply image analysis

• Prepare up to 240 tissue cores per hour

• TMA success rate up to 99%

• Tissue preparation cycle time of 15secs

• Positional accuracy of 5 μm at recipient blocks

• Automatic calibration

Recipient Block Mold Kit

Core size : 1mm / 170 holes (10 x 17)

Core size : 3mm / 40 holes (5 x 8)

Core size : 1.5mm / 150 holes (10 x 15)

Core size : 5mm / 15 holes (3 x 5)

Core size : 2mm / 70 holes (7 x 10)

Recipient block mold kit is an alternative solution for the users to prepare the recipient block by themselves. The

recipient block can be used to excute TMA works with the manual tissue microarrayer called Quick Ray. Furthermore,

the researchers can prepare the hundreds of recipient blocks from a mold kit. For those who concerns over the price

of premade recipient blocks, Quick-Ray Mold Kit is an alternative solution. Made from silicon rubber, Quick-Ray

Mold kit allows users to build paraffin recipient blocks by themselves at a lower cost. The core sizes of each mold is

perfectly match with punchers of Quick-Ray. If stored and handed with care, hundreds of paraffin recipient blocks

can be produced by the Quick-Ray Mold Kit. But this recipient blocks can be applicable only for the manual tissue

microarrayer.

01Place the Recipient

block Mold kit in a dry

oven for 30 minutes at

70~80°C to warm-up

the mold kit.

04Dispense enough

liquid paraffin into the

embedding cassette

02Dispense liquid paraffin

(60~65°C) slowly into

the mold kit until the

top of core rods are

fully submerged.

05Solidify the embedding

cassette and the mold

kit at a normal room

temperature or at

about 4°C for 30~60

minutes.

If solidified at he lower

temperature, the block

may have cracks in it.

AParaffin dispense should

be done so slowly that

no bubbles are to be

formulated among the

core rods.

BWhen some bubbles are

formulated, remove them

with heated forceps.

06Separate the mold kit

from the embedding

cassette slowly and

carefully.

03Place an embedding

cassette on the mold

kit.

07Trim paraffin around

the periphery of the

recipient block.

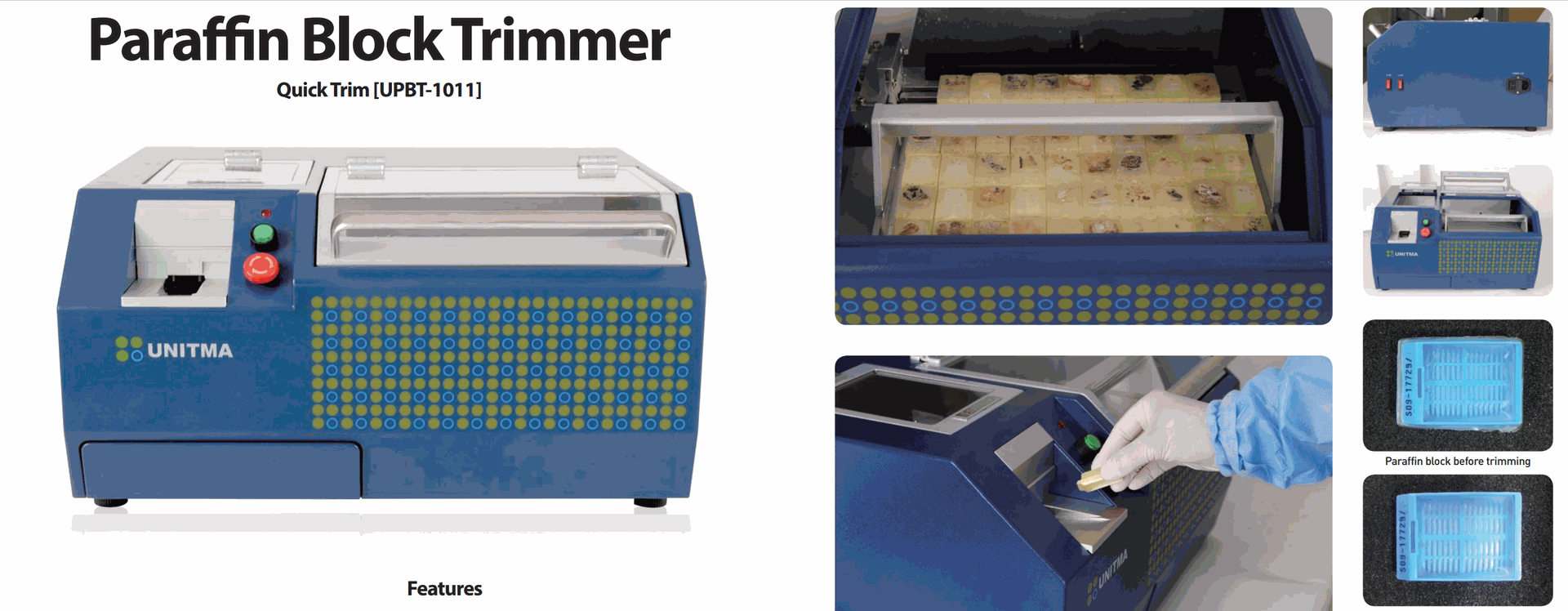

Paraffin Block Trimmer

Quick Trim [UPBT-1011]

Paraffin block before trimming

Paraffin block after trimming

Specification

List Description

Power supply voltages 110 VAC / 220 VAC, 50/60 Hz

Weight (net) 47kg

Max Size (W x D x H) 580 x 477 x 280 mm

Operating temperature range Room temperature

Relative humidity Max. 80% non-condensing

Humidity during transportation/storage < 80%

Trimming capacity Max. 750 blocks per hour

Operating environment Indoor use only

Certification / Approval ISO / CE / FCC

The Paraffin Block Trimmer (generally called Wax

Trimmer, Paraffin Trimmer, Wax Remover, Paraffin

Remover, Dewaxer, etc) is one of the histology

equipments used for the histopathology. The Paraffin

Block Trimmer enables the researchers to trim the

paraffin blocks automatically.

This instrument removes only paraffin residues

around the paraffin blocks without damage to the

tissue samples or the plastic cassette.

When users load the paraffin blocks on the inlet of the

instrument after the embedding process, the blocks

move into the trimming module to trim the paraffin

residues and the trimmed blocks are arrayed by 50

blocks in order in the array plate.

Eventually, this instrument also enables to reduce

the manually trimming time and to prevent the

users from any injuries caused by the conventional

trimming tools.

Features

• Save labor time of researchers

• Protect researchers from any physical damages

which may be caused by conventional trimming

tools.

• Max. 750 paraffin blocks can be trimmed in an hour.

• Semipermanant life time of trimming modules

• Accept the various kinds of the embedded blocks.

• 50 blocks can be trimmed at one time and continue

trimming by replacing the array plate with a new

one.

• The trimmed blocks are arrayed in order at the array

plate.